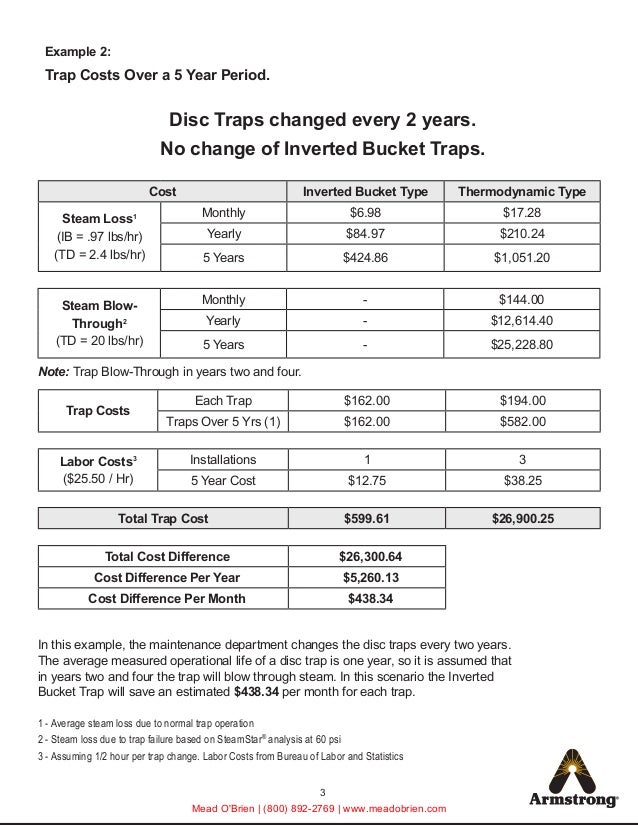

Inverted Bucket Steam Trap Failure

We use cookies to give you the best experience on our website.

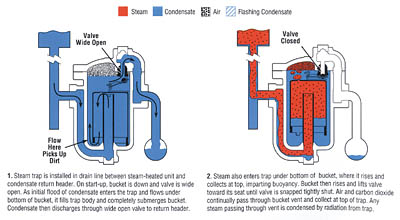

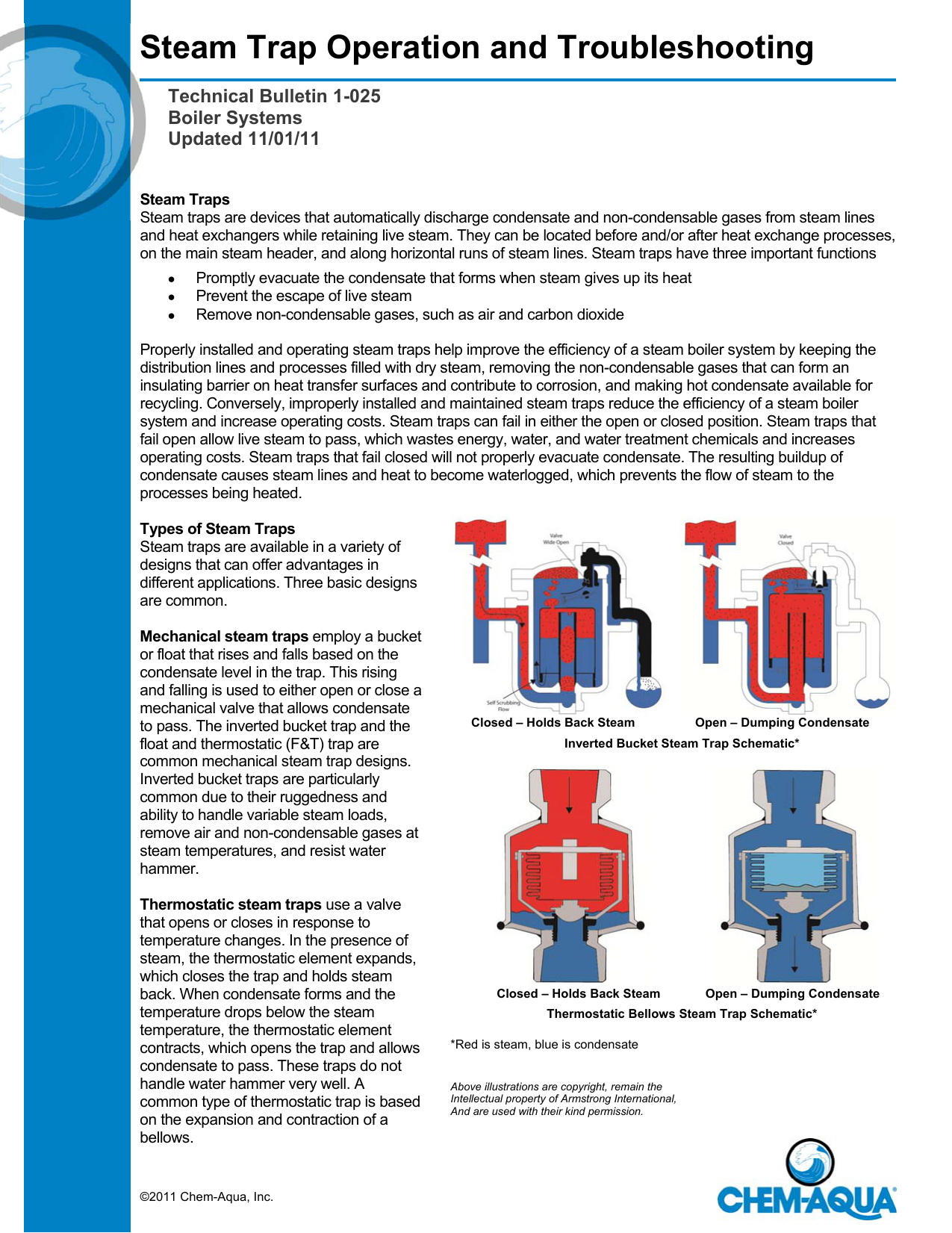

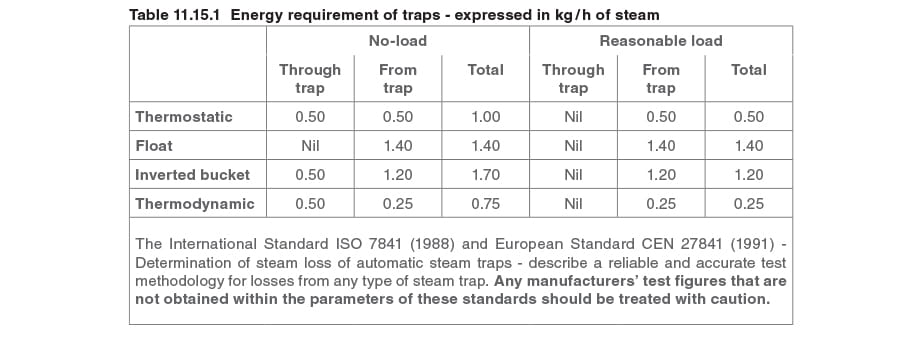

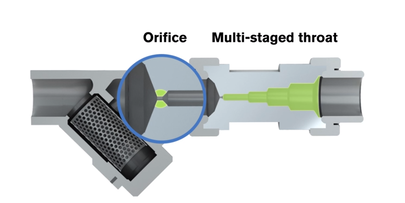

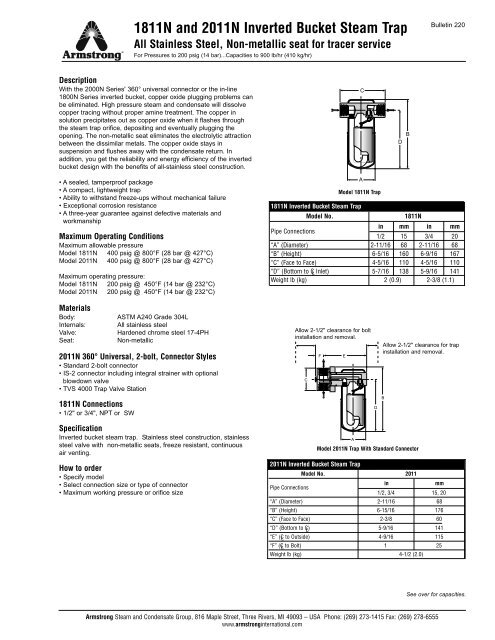

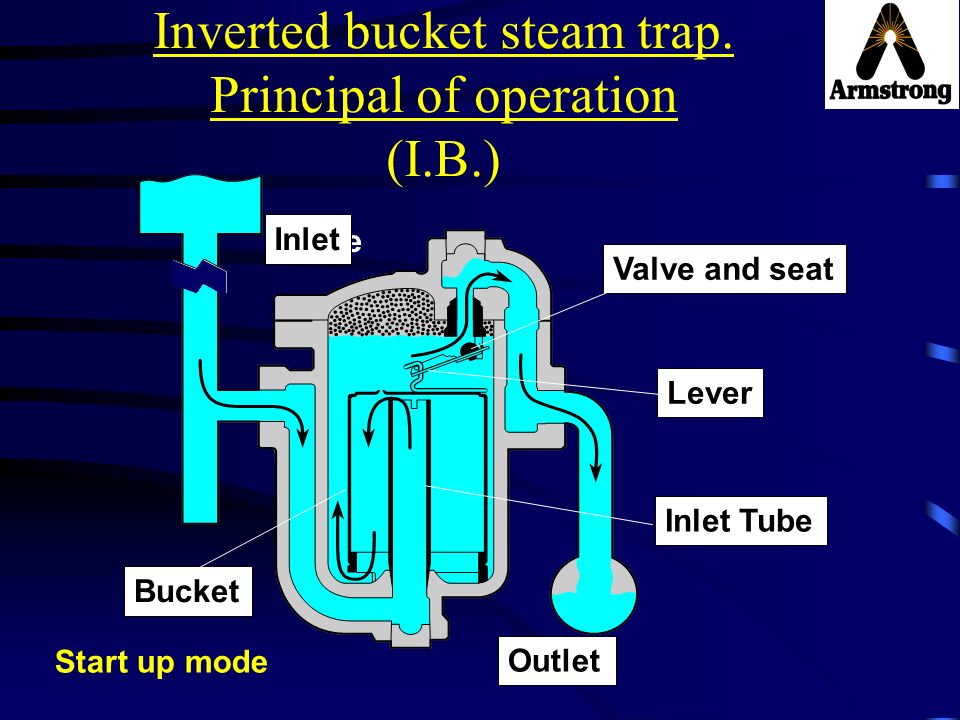

Inverted bucket steam trap failure. The energy efficient inverted bucket steam trap in 1911. The inverted bucket steam trap is shown in figure 11 3 3. As its name implies the mechanism consists of an inverted bucket which is attached by a lever to a valve. For an accurate diagnosis of trap condition obtaining help from an experienced professional that uses specialized equipment is key.

An inverted bucket floats in condensate that surrounds the bucket. In the years since customers savings have proven again and again that knowledge not shared is energy wasted. Inverted bucket traps rely on the density difference between steam and water to drain condensate as it forms. Figure 11 3 3 shows the method of operation.

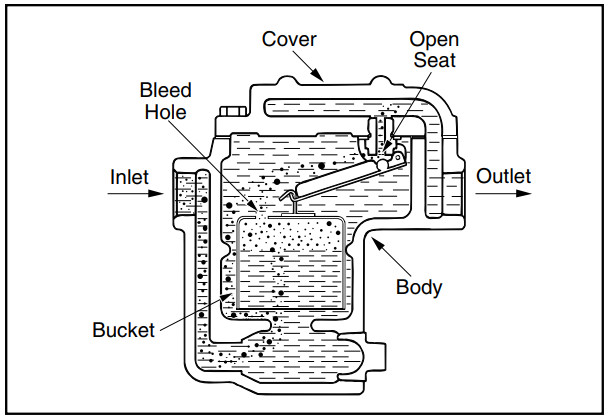

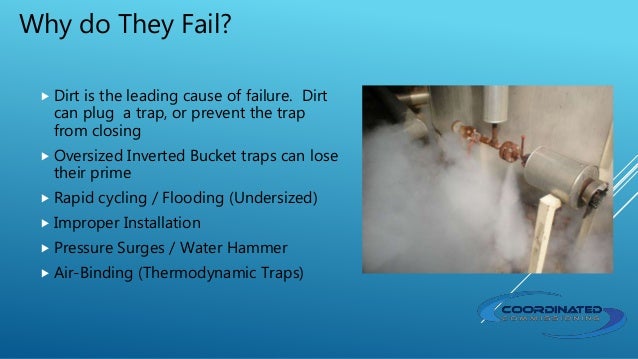

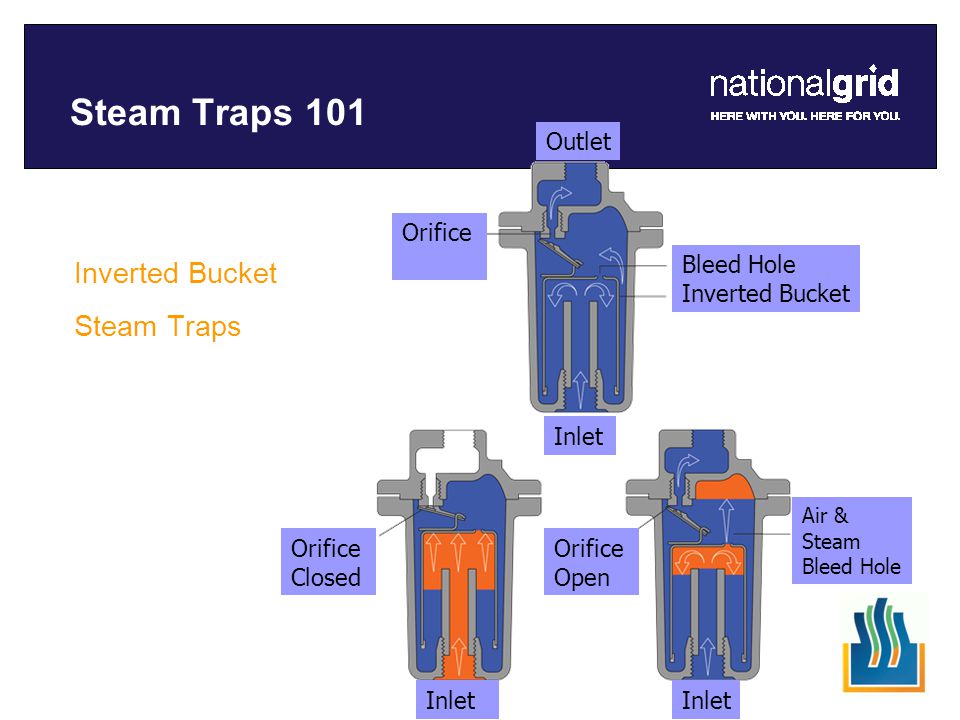

Once failure is confirmed the trap should be either repaired or replaced as soon as possible to capture the maximum gain on investment. An essential part of the trap is the small air vent hole in the top of the bucket. The inverted bucket steam trap energy efficient because it s so reliable the inverted bucket is the most reliable steam trap operating principle known the heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure since the bucket is open at. If you continue without changing your cookie settings we assume that you consent to our use of cookies on this device.

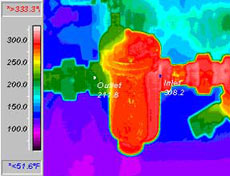

A steam trap selection guide float thermostatic inverted bucket bimetal thermostatic impulse and thermodynamic disc steam traps sponsored links a steam trap is a self contained valve which automatically drains the condensate from a steam containing enclosure while remaining tight to live steam or if necessary allowing steam to flow at. Trap priming all inverted bucket steam traps are basically self priming on initial start up and should require no further priming normally on a cold start up of the equipment being trapped enough condensate reaches the steam trap body to create the necessary water seal prime before steam reaches it. The same is true of listening to a steam trap. With a fine instrument you can even hear the snap crackle pop of steam passing across the head and seat of a wiredrawn inverted bucket trap.

This section has grown out of our decades. Armstrong s developments and improvements in steam trap design and function have led to countless savings in energy time and money. Testing steam traps is an important part of managing your steam trap population. The inverted bucket within the trap will rest on the bottom of the trap body keeping the valve open and allowing condensate to be discharged figure a in the top of the bucket there is a small bleed hole which allows air to escape from inside the bucket and exit through the outlet port figure b when steam arrives through the inlet of the trap it fills the inverted.

When listening to a quality speaker system the nuances of what was actually recorded opens your ears to new level of listening.