Ion Exchange Resin Column Design

Based on the experiment results and calculation the ion exchange is design as follows.

Ion exchange resin column design. Calenergy minerals is using an anionic dowex resin to recover zinc from geothermal brines in a series of ion exchange columns. The recovered zinc is eluted with pure water and transferred intermittently to be treated by further refining 2. Basic column types are shown in another page. 10 days material cost of resin per m3 water produced.

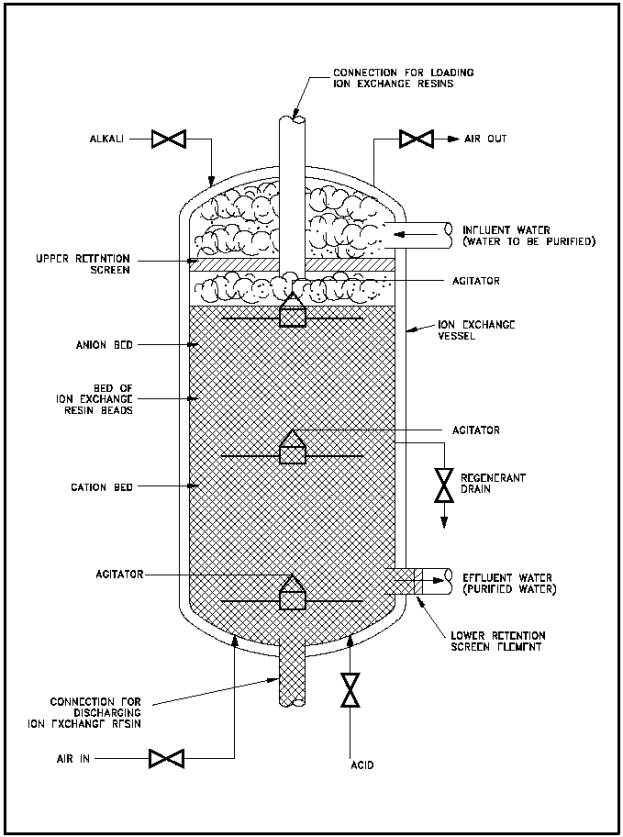

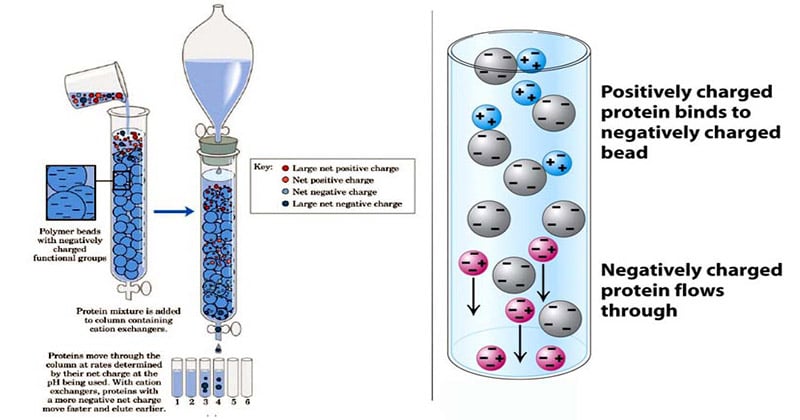

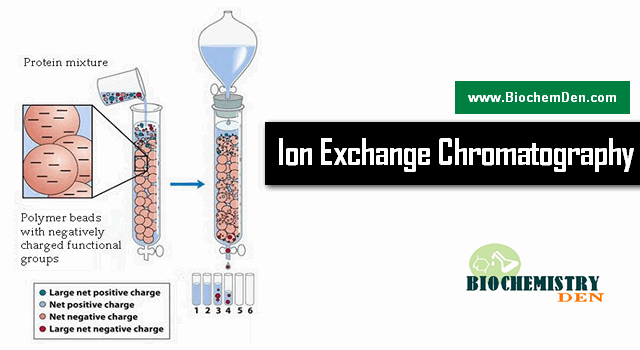

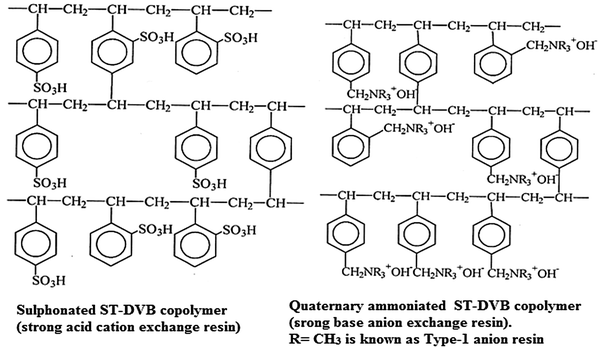

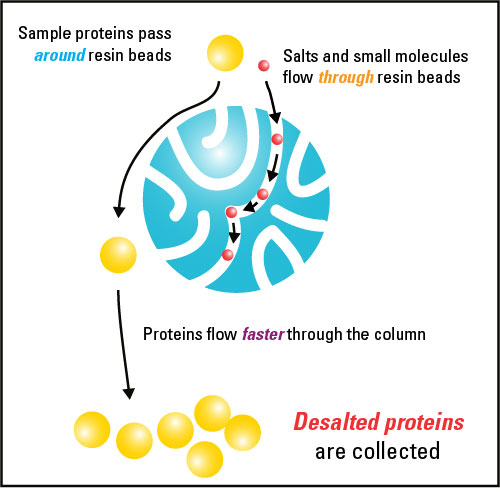

A demineralizer system consists of one or more ion exchange resin columns which include a strong acid cation unit and a strong base anion unit. Ion exchange plant design some basic principles you will not find here a complete plant design manual. For example metal contaminants are. Continuous ion exchangers consist of two columns in parallel.

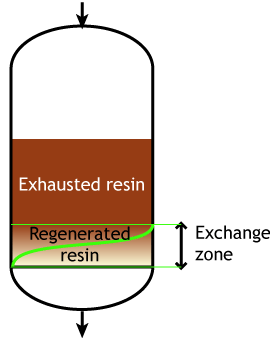

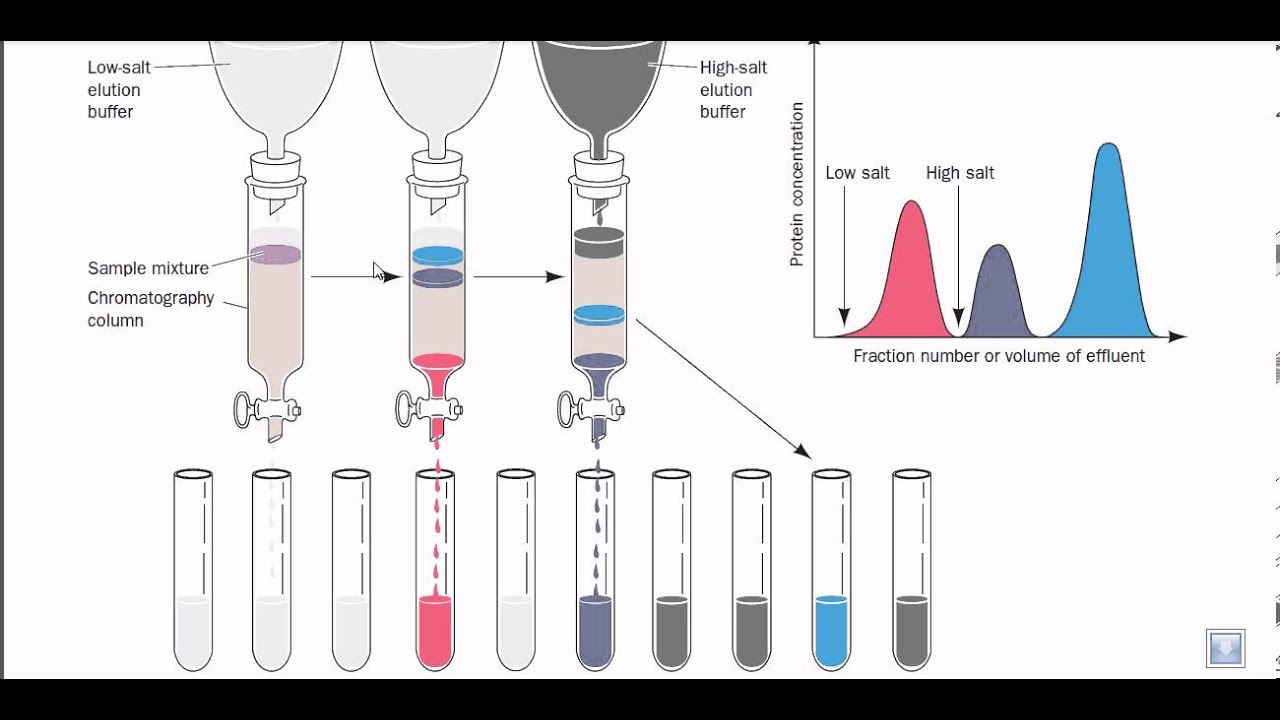

The optimum column diameter must be a balance between the resin bed height the ratio of resin height to diameter h d and the linear velocity. Design procedures the breakthrough curves for an ion exchange column and an adsorption column are similar. The aim of the work described in this report was to design an ion exchange column for the removal of ammonium ions from ro permeate. Therefore the same procedures used for the design of adsorption columns may be used for ion exchange columns.

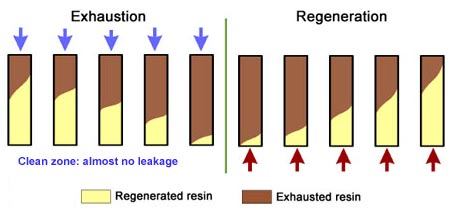

How to design an ion exchange resin system. The contacting techniques are almost identical. Usage examples continuous ion exchangers are used when it is imperative that product be continually generated. One variation of the standard design uses a layer of weak acid resin on top of strong acid cation resin.

Goro nickel cobalt project in new. The ion exchangers used in this research project were i clinoptilolite a naturally occurring zeolite and ii a resin in h form with functional group sulfonic acid lewatit s2568h. Bigger vessels with up to 4 0 m are sometimes built but the aspect ratio of the resin bed width height becomes unfavourable and very precise distribution and collection systems must be fitted to ensure an even flow of the water during service and. 1 2 minutes column height.

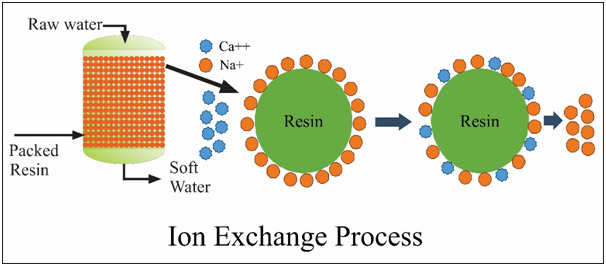

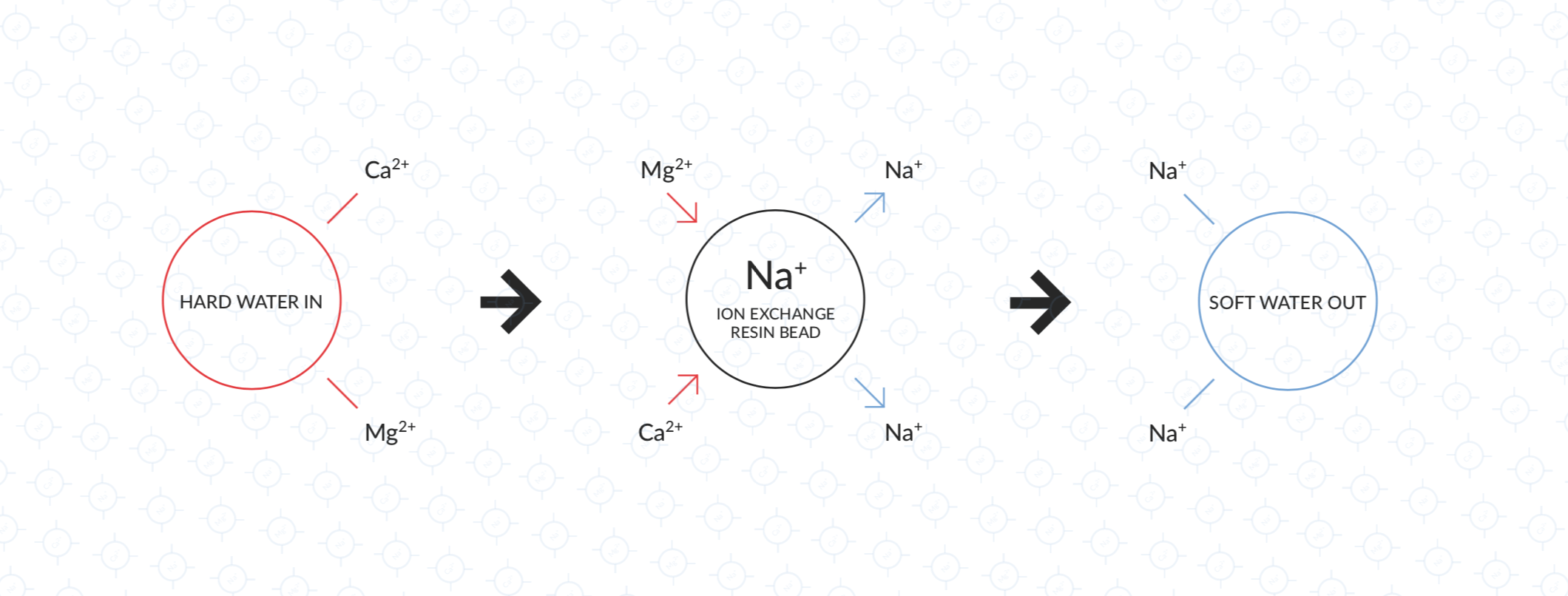

Rohm and haas ion exchange ion exchange introduction 4 fd sep 2008 to soften water you take a cation exchange resin on which the mobile ion inside the beads is sodium na and you pass the hard water through a column filled with the sodium form resin. Ion exchange takes place in one column while the resin in the second column is being regenerated resulting in continuous operation. O the scale up approach o the kinetic approach. Only a few general recommendations to ensure that an ion exchange system is designed economically and to achieve good performance and a simple but detailed example.

4 each with a capacity of 120m3 h surface loading. The design of the vessels should give a maximum resin bed depth while limiting the pressure drop across the resin bed to 1 bar. The hardness ions ca and mg move into the resin beads and each of these divalent. With the exception of the resin.