Iso 7 Clean Room

Class 10 000 associated eu gmp grade.

Iso 7 clean room. The latter to cleanrooms where biocontamination may be an issue. The cleanroom classification standards fs 209e and iso 14644 1 require specific particle count measurements and calculations to classify the cleanliness level of a cleanroom or clean area. An iso 7 zone has 30 to 60 air changes per hour. Most cleanrooms fall into the class 6 7 or 8 categories.

Terms definitions and units. To comply with performance requirements the as built empty room should be tested and benchmarked followed by testing and documentation of the at rest and operational states. Evaluation and interpretation of data. See the maximum allowable concentrations by cleanroom class on our cleanroom classifications page.

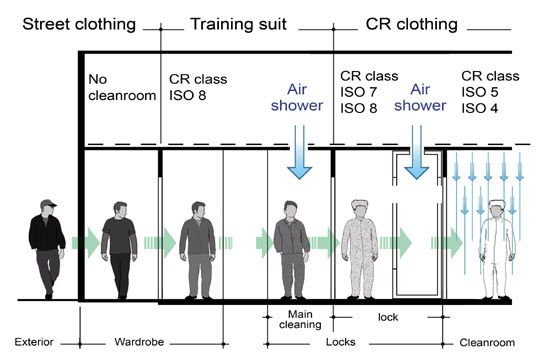

In the uk british standard 5295 is used to classify cleanrooms. 60 90 for iso 7 cleanrooms organisations typically measure micron sizes 5 0µ and 0 5µ. In theory for an entire room to reach iso 6 air cleanliness you need to enter the cleanroom via an iso 8 ante room then go through an iso 7 to finally get into the iso 6 as shown in the image. This is because a cleanroom may be rated iso 6 at rest but at iso 7 during operation.

A clean room may be rated iso 6 at rest but at iso 7 during operation see table 1. Iso 14644 1 and iso 14698. Iso 7 cleanroom class 10 000 explained. Information on iso 14644 1 2015 class 7 cleanroom classification.

C recommended air changes per hour ach. In reality however you can reach an iso 6 clean room with 1 recommendation is 2 airlock. How to clean a class 10 000 iso class 7 cleanroom. Federal standard 209e equivalent.

Iso 7 clean room classifications. Cleanroom design and construction. Is an innovative leader in design engineering manufacturing and construction of clean rooms throughout the us. The former applies to clean rooms in general see table below.

Before an iso 7 cleanroom is installed an iso 8 airlock or gowning room is set up prior to entering the iso. An iso 7 clean room class 10 000 cleanroom is a hard sided wall manufactured facility that utilizes hepa filtration systems to maintain air cleanliness levels of a maximum of 10 000 particles 0 5µm per cubic foot. Clean rooms west inc.