Iso 8 Clean Room Pressure

Is an innovative leader in design engineering manufacturing and construction of clean rooms throughout the us.

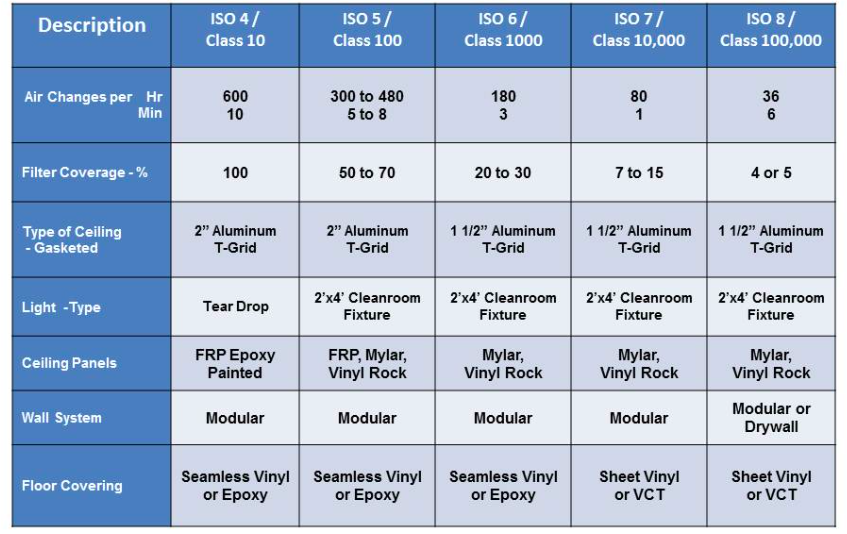

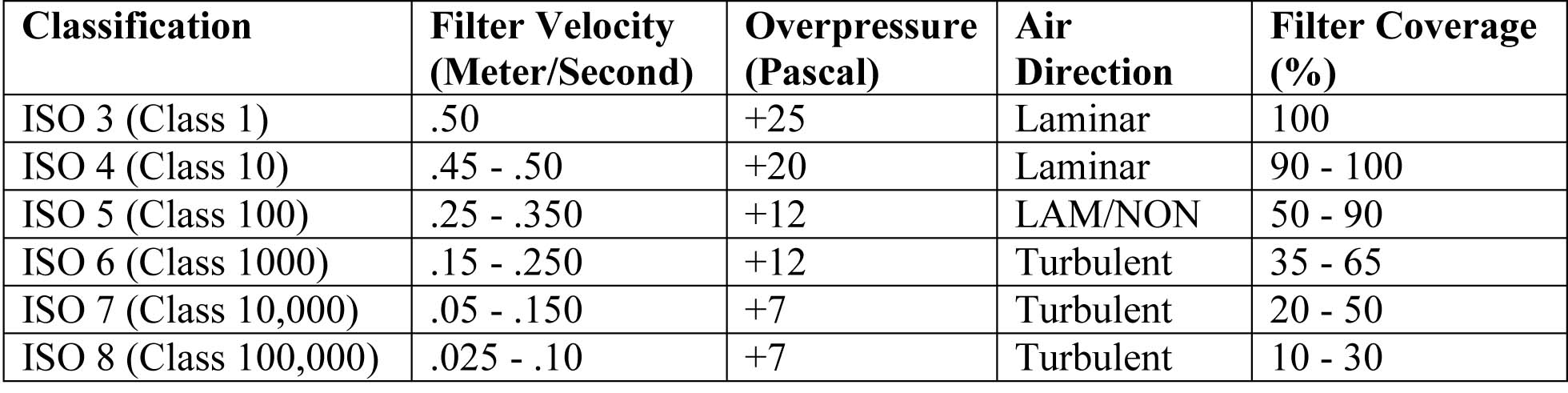

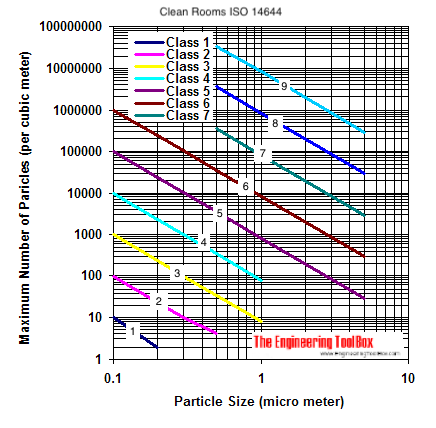

Iso 8 clean room pressure. Iso clean room classifications are rated according to how much of a particulate of a specific size exists per cubic meter within a given enclosure see second chart. Iso 8 clean room clean rooms west inc. Temperature humidity and pressure are controlled as. The airflow must be greater in the adjacent room.

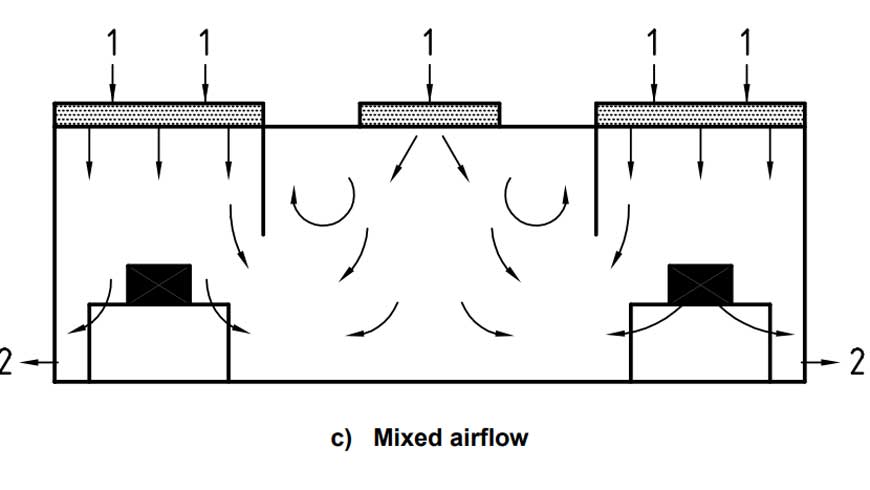

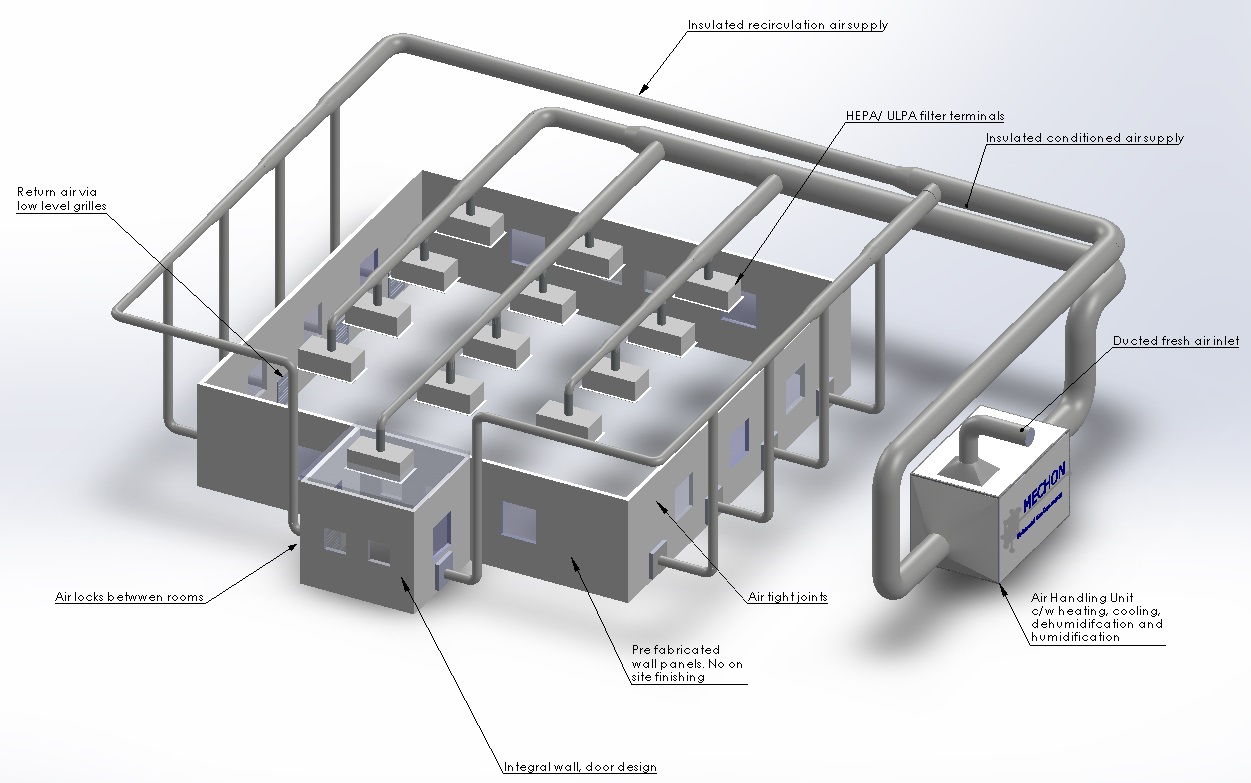

Iso 8 cleanroom particle specifications. Iso 8 clean rooms do not require certain particle sizes to be tested either because concentration levels are too high or low to be tested but it cannot be zero. A cleanroom is defined by iso14644 1 as a room in which the concentration of airborne particles is controlled and which is constructed and used in a manner to minimize the introduction generation and retention of particles inside the room and in which other relevant parameters e g. Terms definitions and units.

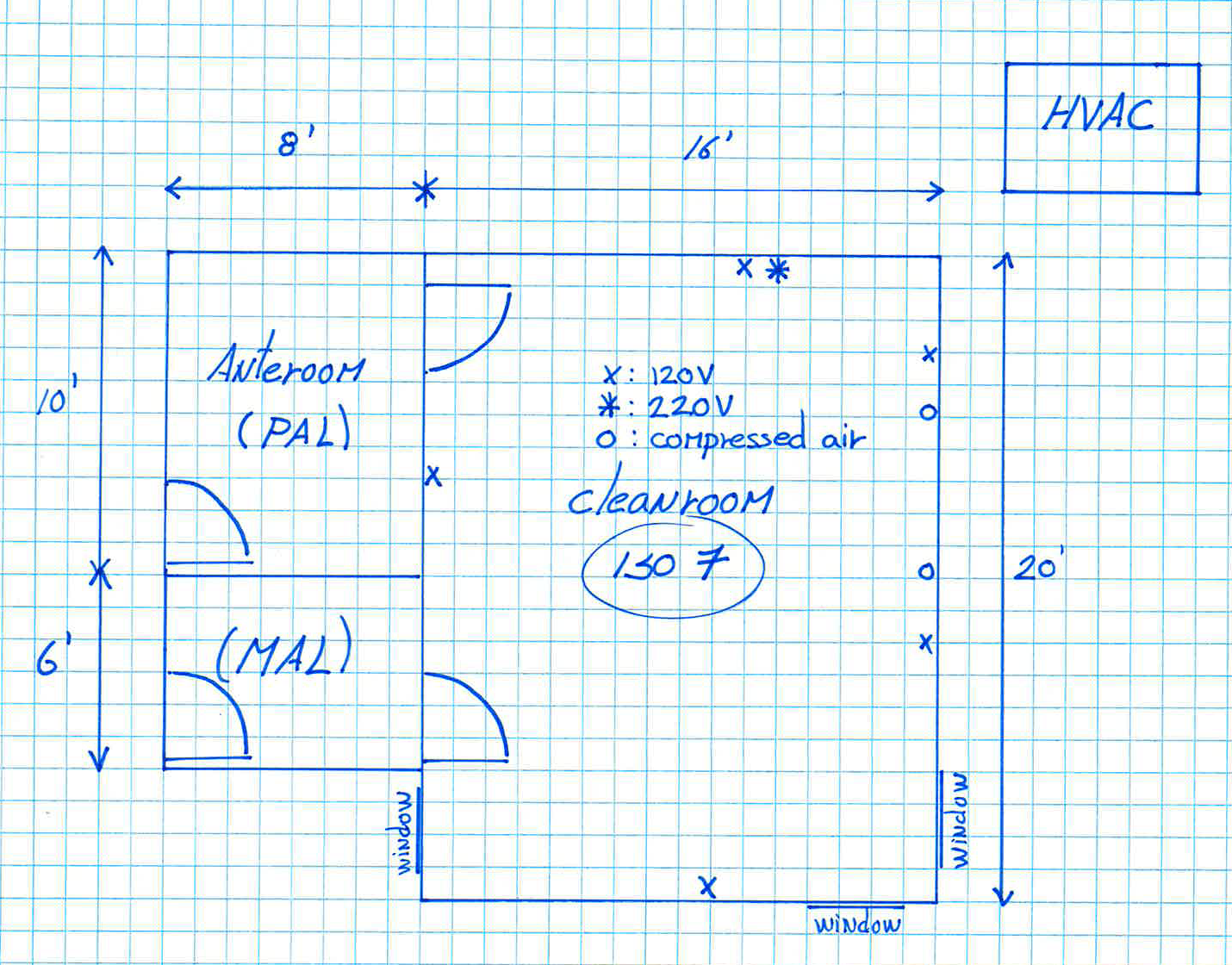

Evaluation and interpretation of data. Cleanroom design and construction. I would like to know what is the minimum pressure differential required for iso class 8 clean room. I am asking this question because one of our clean room has a pressure differential of 0 02 inches water clean room to gowning and 0 01 inches water gowning to outside.

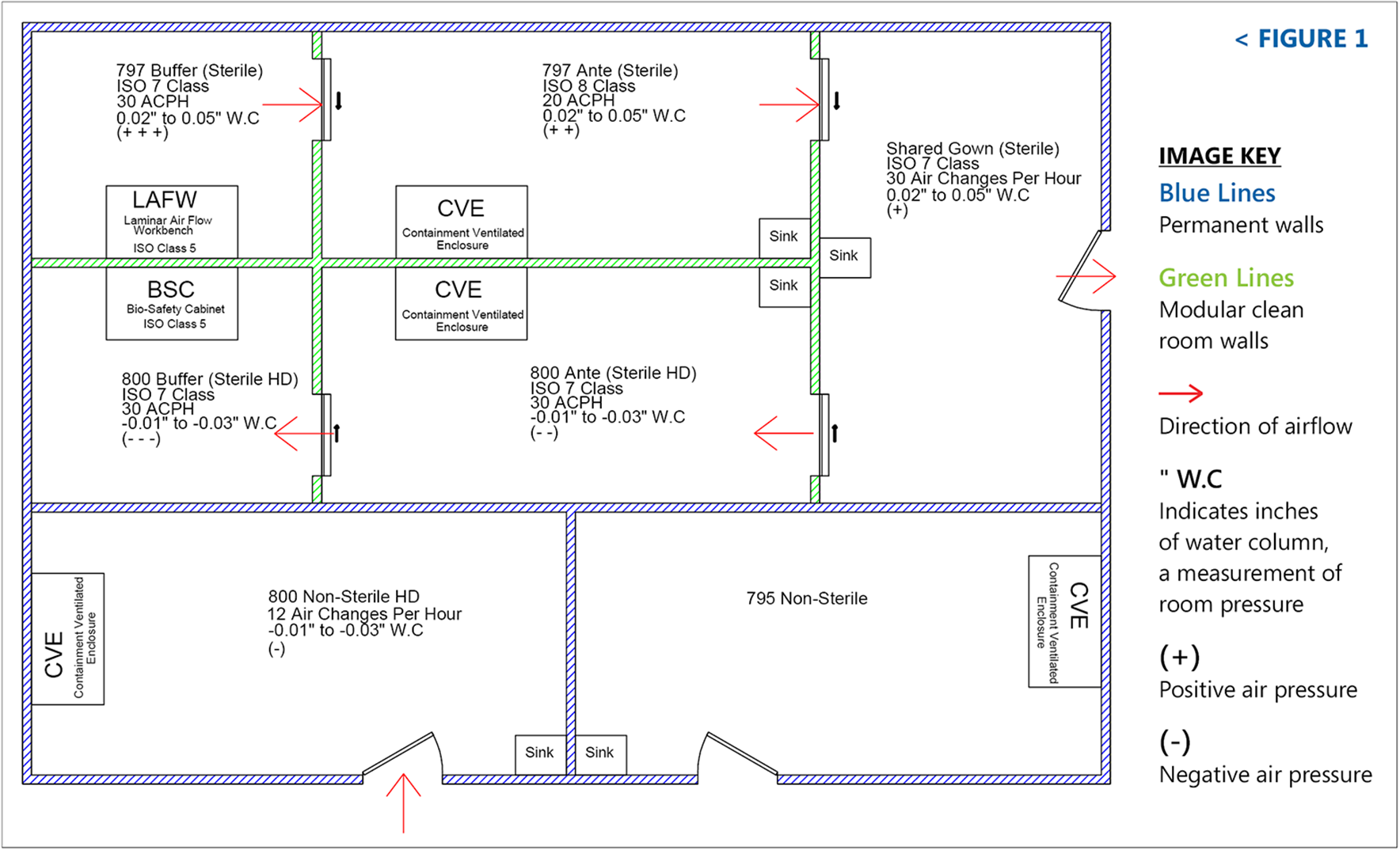

In a negative pressurised cleanroom the opposite occurs. Usually manufacturers will define an airborne particulate concentration standard class such as iso 14644 1 iso 8 at rest outline gowning and a pressure cascade regime defining a clean corridor design or a dirty corridor design. The concentration of particles that are 0 5 µm should be below 3 520 000. In reality however you can reach an iso 6 clean room with 1 recommendation is 2 airlock.

Positive pressure prevents dirty air from entering into the cleanroom. Clean room classifications are based on an eight class rating system with an iso class 1 cleanroom being rated the most particle free and iso class 8 allowing the most particles. For iso class 8 particles smaller than 0 5 µm aren t considered. In theory for an entire room to reach iso 6 air cleanliness you need to enter the cleanroom via an iso 8 ante room then go through an iso 7 to finally get into the iso 6 as shown in the image.

We are one stop source for the successful implementation of any cleanroom development project from concept to completion.