Johnsonite Stair Treads Maintenance

Thoroughly sweep or vacuum the flooring to remove all loose dirt and grit.

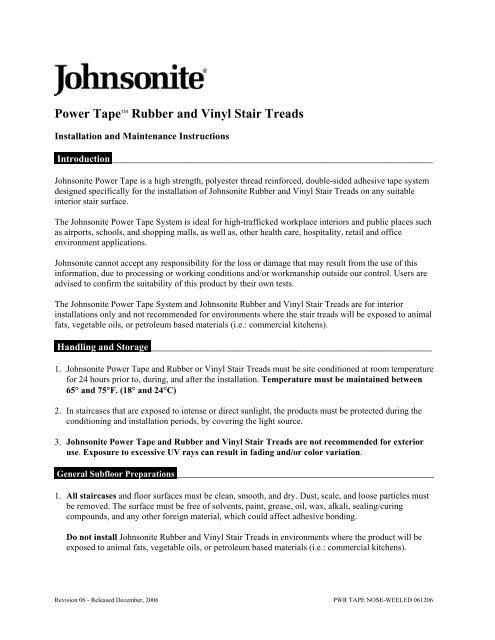

Johnsonite stair treads maintenance. Rubber and vinyl stair treads 1. Any open spaces at the nosing between the step and the tread must be filled with johnsonite 930 epoxy caulking compound nose filler. Safety happiness productivity. A minimum temperature of 55 f 13 c must.

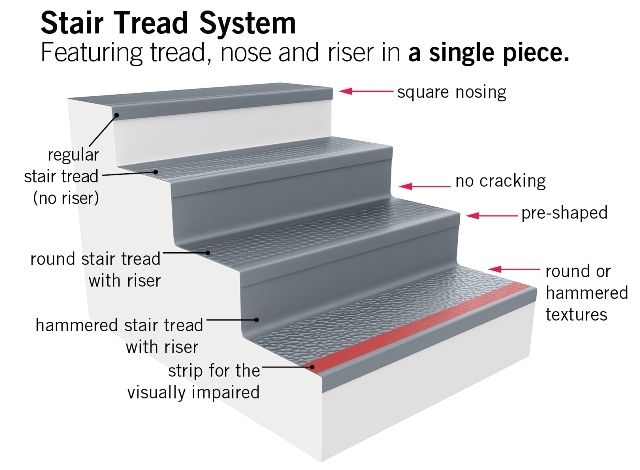

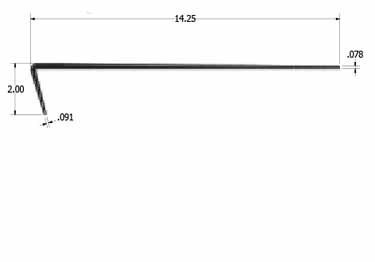

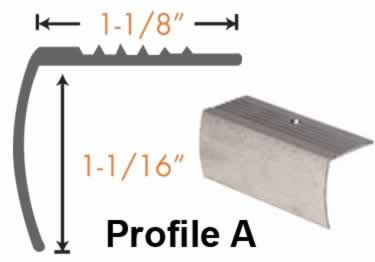

Since each step on a staircase can vary slightly in width depth and squareness tarkett recommends scribing each tread nosing and riser to ensure proper fit on the step. Fitting the stair tread nosing. The nose of the tread must fit tightly against the face of the stair riser or nosing. Daily cleaning is recommended.

Prepare a cleaning solution using one of the recommended ph. Maintenance 72 hours after installation is completed initial maintenance procedures must be implemented in accordance with manufacturer s requirements. Back of the tread must be cleaned with denatured alcohol to ensure proper adhesion. Johnsonite stair treads nosings risers stringers and adhesives must be site conditioned at room temperature for 48 hours prior to during and after installation.

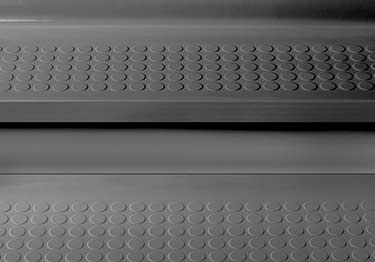

Johnsonite stair treads must be trimmed to fit for both width and depth of the stair step and dry laid on each step prior to adhesive tape application and installation. Refer to johnsonite rubber stair tread maintenance instructions for complete. It is very important to clean the stair treads at a frequency consistent with the amount and type of traffic and soil conditions. Room temperature must be maintained between 65 and 85 f 18 and 29 c with hvac system operating.

Johnsonite stair treads nosings and risers must be trimmed to proper size and dry laid prior to the application of adhesive.